Our Services

How We Power Your EV Vision ?

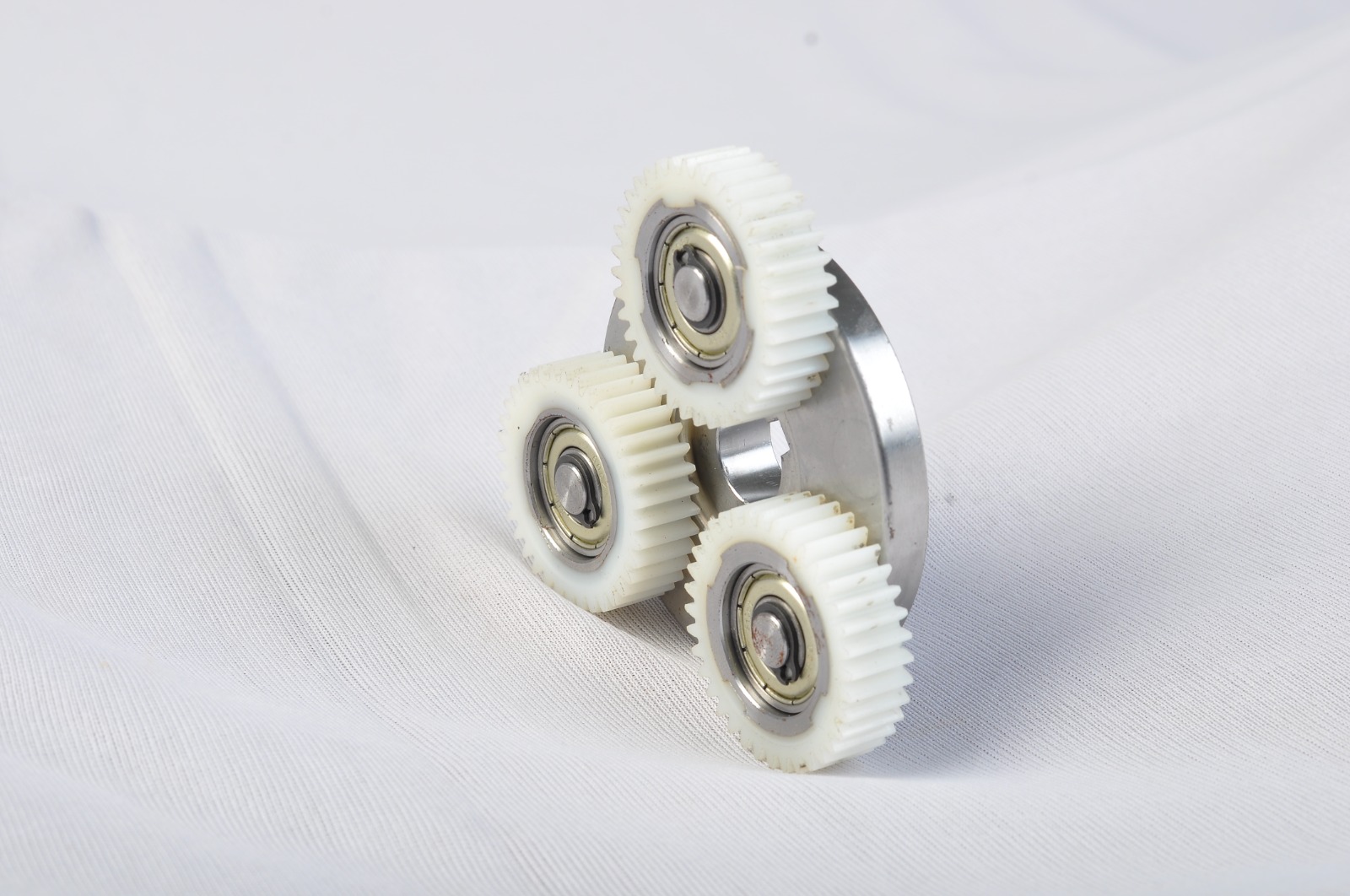

Custom-Built Mechanical Parts for E-Bike Innovation

EV Mechanical Component Manufacturing

We manufacture custom mechanical parts built specifically for the EV industry, with a focus on performance, durability, and consistency. Our components are ready for mass production and optimized for electric mobility platforms. Whether it’s for suspension systems, frame fittings, motor mounts, or drivetrain components—we ensure top-quality outputs every time.

Key Features:

Production-ready parts

Scalable volume manufacturing

Material and process flexibility

Precision and performance-focused

Injection Molding & Blanking Services

Our in-house injection molding facility enables us to produce high-quality plastic parts with tight tolerances and repeatability. This gives our clients full control over product consistency and faster lead times. From prototypes to large batches, our molding solutions are ideal for enclosures, brackets, and lightweight EV components.

Applications:

Lightweight structural parts

High-volume production capability

Consistent surface finish and strength

Blanking Services

With dedicated equipment for metal blanking, we manufacture clean, uniform shapes from sheet metal—forming the base for various EV parts. Our blanking operations support both simple and complex geometries with tight dimensional accuracy, contributing to a lean, scalable manufacturing process.

Highlights:

High-speed, high-volume production

Reduced material waste

Suitable for steel, aluminum, and alloys

Foundation for stamped and machined parts

Forging & Precision Machining (Through Trusted Partners)

For parts that require higher strength, tighter tolerances, or intricate shapes, we offer precision CNC machining and forging solutions through long-term vendor partnerships. These vendors are selected based on consistent quality, capacity, and technical excellence, ensuring seamless integration with our overall supply chain.

Capabilities Include:

Close tolerance CNC machining

Hot and cold forging

Small to large batch sizes

Coating, finishing, and secondary operations

Product Design & Development

We help bring your ideas to life through our product design services, creating detailed 2D/3D models, functional prototypes, and final designs optimized for manufacturing. Whether you need a new part or a redesign of an existing one, our engineers ensure every product is ready for real-world performance.

Our Design Services Include:

Concept ideation and industrial design

CAD modeling and drafting

Prototyping and testing

DFM (Design for Manufacturability)

Reverse Engineering

Need to replicate an existing component with improved accuracy or updated materials? Our reverse engineering service lets you recover, refine, and reintroduce critical parts with confidence. We analyze physical samples, extract key dimensions, and recreate them as fully manufacturable models with scope for design improvements.

Used For:

Legacy or discontinued parts

Supplier transition support

Material upgrades or cost optimization

Quality and tolerance improvements

Precision Engineering for the Future of Mobility

At Ryan Malabar, we specialize in delivering high-quality mechanical components and engineering services tailored for the electric vehicle (EV) sector—especially e-bikes and electrically assisted bicycles. With a deep understanding of the industry’s evolving needs, we offer a robust combination of in-house manufacturing, design expertise, and a reliable vendor network to support businesses from concept to full-scale production.

Why Choose Ryan Malabar ?

At Ryan Malabar, we go beyond manufacturing — we engineer trust, precision, and scalability into every component we deliver. With over a decade of experience in the EV sector, especially in e-bike and light mobility systems, we offer a complete suite of services backed by expertise, quality, and customer-first thinking.